Short Lead Time for Fluorescent Whitening Agent KSN - Optical Brightener EBF-L – Subang

Short Lead Time for Fluorescent Whitening Agent KSN - Optical Brightener EBF-L – Subang Detail:

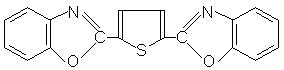

Structural formula

Appearance: Milky white dispersion

Ionicity: non-ionic

Main ingredients: benzothiazole derivatives

Dyeing shade: pure white light

Performance and Characteristics

1. Fluorescent brightener EBF-L is suitable for the whitening and brightening treatment of polyester and its blended fabrics;

2.EBF-L is suitable for exhaust dyeing and pad dyeing process;

3. EBF-L has excellent light fastness characteristics, up to level 7;

4. EBF-L has good stability to acid/alkali, hard water, peroxide and hypochlorous acid compounds;

5. EBF-L is very suitable for alkaline dyeing process.

Instructions

1. High temperature exhaustion process

Prescription: Fluorescent Brightener EBF-L 0.1-1.0% o.w.f Dispersant: 0.5-1g/L

Acetic acid adjusts pH=4.5-5.5

Process: 120-130℃×20-40 minutes

2. Continuous pad dyer

Prescription: Fluorescent Brightener EBF-L 2-10g/L Other additives: xg/L

Process: 180-185℃×30 seconds; rolling rate: 60-100%

3. One-step process of resin finishing

Prescription: fluorescent brightener EBF-L 1-10g/L silicone oil softener: 10-40g/L resin: (melamine) g/L resin catalyst g/L

Process: Drying: 130℃×1 minute Rolling rate: 40-60%; Fixation: 160-185℃×2-3 minutes

Precautions

1. The fluorescent whitening agent EBF-L must be fully stirred before use to ensure the whiteness and color consistency of the processed fabric.

2. Before whitening the fabrics bleached by oxygen bleaching, the residual alkali on the fabrics must be fully washed to ensure that the whitening agent is fully colored and the color is bright.

3. Fluorescent brightener EBF-L is a high-temperature type polyester fluorescent brightener. The dyeing temperature and setting temperature must meet the requirements of the above process to ensure the normal color of the fluorescent brightener. If you need to dye at room temperature, you can use carrier dyeing Method.

4. Fluorescent brightener EBF-L has excellent light fastness, and fabrics with special processing requirements for light fastness can be processed with this product.

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Short Lead Time for Fluorescent Whitening Agent KSN - Optical Brightener EBF-L – Subang , The product will supply to all over the world, such as: European, Japan, Palestine, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!