PP plastic, also known as polypropylene, is a linear polymer with high density, no side chains, and high crystallinity. It has excellent comprehensive properties and is widely used in fields such as wire drawing, fiber, household appliances, and pipes. Due to the widespread use of polypropylene plastics, waste PP has become one of the most abundant waste polymer materials in recent years. At present, the main ways to treat waste PP include incineration for energy supply, catalytic cracking for fuel preparation, direct utilization, and resource reuse. Considering factors such as technical feasibility, cost, energy consumption, and environmental protection in the process of treating waste PP, PP recycling and reuse is currently a commonly used, effective, and advocated approach to treating waste PP.

Due to the influence of light, heat, oxygen, external force and other factors during the use of PP, the molecular structure of PP has changed, and the PP products have become yellow and brittle, resulting in the obvious deterioration of the toughness, stability and processability of PP. It is difficult to meet the user’s requirements for injection products made directly from old PP. Therefore, it is necessary to add additives to improve the performance of recycled PP and achieve high-performance waste PP. Among them, the Optical brightener for PP injection molding can increase the whiteness and brightness of the product, improve the yellowing of regenerated PP, reduce the weather resistance and other problems, and is an indispensable auxiliary for PP injection molding manufacturers.

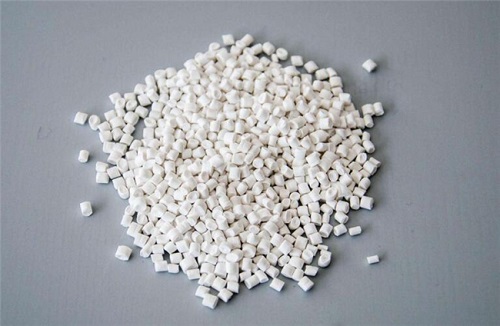

The production process of PP plastic has high requirements for the decomposition temperature of Optical brightener, such as injection molding, wire drawing and other production temperatures. If the selected whitening agent model does not meet this requirement, it will become invalid or even gelatinize. Optical brightener OB has always had the reputation of Wan essential oil. It not only meets the requirements of PP plastics perfectly, but also has a small amount of addition. At present, it has been recognized by domestic users. It is a whitening agent with high cost performance for PP plastics. The whiteness value and stability of Optical brightener OB are relatively good, and its light transmittance is high, and its addition amount is easy to control, which will not affect the production process of PP plastics. Generally, the addition amount is between 0.01% and 0.05%, and the whiteness and brightness of the product will be greatly improved.

Optical brightener OB not only has a good whitening and brightening effect on PP plastics, but also has a very good whitening effect on PVC, PP, PS, ABS and other plastics. Shandong Subang Fluorescence Technology Co., Ltd. has been focusing on the production and research and development of Optical brightener for more than 20 years. If you want to make your products white and bright, please contact Shandong Shubang. We provide you with professional technical guidance and one-on-one technical services!

Post time: Jul-21-2023