Free sample for Optical Brightener Er - Optical Brightener EBF-L – Subang

Free sample for Optical Brightener Er - Optical Brightener EBF-L – Subang Detail:

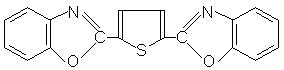

Structural formula

Appearance: Milky white dispersion

Ionicity: non-ionic

Main ingredients: benzothiazole derivatives

Dyeing shade: pure white light

Performance and Characteristics

1. Fluorescent brightener EBF-L is suitable for the whitening and brightening treatment of polyester and its blended fabrics;

2.EBF-L is suitable for exhaust dyeing and pad dyeing process;

3. EBF-L has excellent light fastness characteristics, up to level 7;

4. EBF-L has good stability to acid/alkali, hard water, peroxide and hypochlorous acid compounds;

5. EBF-L is very suitable for alkaline dyeing process.

Instructions

1. High temperature exhaustion process

Prescription: Fluorescent Brightener EBF-L 0.1-1.0% o.w.f Dispersant: 0.5-1g/L

Acetic acid adjusts pH=4.5-5.5

Process: 120-130℃×20-40 minutes

2. Continuous pad dyer

Prescription: Fluorescent Brightener EBF-L 2-10g/L Other additives: xg/L

Process: 180-185℃×30 seconds; rolling rate: 60-100%

3. One-step process of resin finishing

Prescription: fluorescent brightener EBF-L 1-10g/L silicone oil softener: 10-40g/L resin: (melamine) g/L resin catalyst g/L

Process: Drying: 130℃×1 minute Rolling rate: 40-60%; Fixation: 160-185℃×2-3 minutes

Precautions

1. The fluorescent whitening agent EBF-L must be fully stirred before use to ensure the whiteness and color consistency of the processed fabric.

2. Before whitening the fabrics bleached by oxygen bleaching, the residual alkali on the fabrics must be fully washed to ensure that the whitening agent is fully colored and the color is bright.

3. Fluorescent brightener EBF-L is a high-temperature type polyester fluorescent brightener. The dyeing temperature and setting temperature must meet the requirements of the above process to ensure the normal color of the fluorescent brightener. If you need to dye at room temperature, you can use carrier dyeing Method.

4. Fluorescent brightener EBF-L has excellent light fastness, and fabrics with special processing requirements for light fastness can be processed with this product.

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Free sample for Optical Brightener Er - Optical Brightener EBF-L – Subang , The product will supply to all over the world, such as: Iran, Poland, Cannes, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.