Optical brightener OB Fine

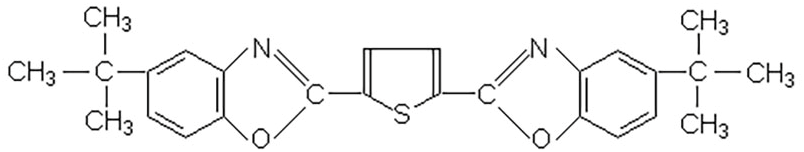

Structural formula

Product Name: Optical brightener OB Fine

Chemical Name: 2,5-thiophenediylbis(5-tert-butyl-1,3-benzoxazole)

C.I.:184

CAS NO.:7128-64-5

Specifications

Molecular formula: C26H26N2O2S

molecular weight: 430

Appearance: light yellow powder

Tone: blue

Melting point: 196-203℃

Purity: ≥99.0%

Ash: ≤0.1%

Particle size: Pass 300 mesh

Maximum absorption wavelength: 375nm(Ethanol)

Maximum emission wavelength: 435nm(Ethanol)

Properties

Optical brightener OB Fine is a kind of benzoxazole compound, it is odorless, hard to dissolve in water, soluble in paraffin, fat, mineral oil, wax and common organic solvents. It can be used for whitening thermoplastic plastics, PVC, PS, PE, PP, ABS, Acetate fiber, paint, coating, printing ink, etc. It can be added at any stage in the process of whitening the polymers and make the finished products emit a bright bluish white glaze.

Application

Optical brightener OB Fine is one of the best brighteners widely used in plastics and fibers and has the same whitening effect as Tinopal OB. It can be used in thermoplastics, polyvinyl chloride, polystyrene, polyethylene, polypropylene, ABS, acetate, and it can also be used in varnishes, paints, white enamels, coatings, and inks.It also has a very good whitening effect on synthetic fibers.It has the advantages of heat resistance, weather resistance, non-yellowing, and good color tone.It can be added to the monomer or prepolymerized material before or during polymerization, condensation, addition polymerization, or added in the form of powder or pellets (i.e masterbatch) before or during the formation of plastics and synthetic fibers.

Reference usage:

1 PVC:

For soft or rigid PVC:

Whitening: 0.01-0.05% (10-50g/100KG material)

Transparent: 0.0001-0.001%(0.1g-1g/100kg material)

2 PS:

Whitening: 0.001% (1g/100kg material)

Transparent: 0.0001-0.001 (0.1-1g/100kg material)

3 ABS:

Adding 0.01-0.05% to ABS can effectively eliminate the original yellow color and achieve a good whitening effect.

4 Polyolefin:

Good whitening effect in polyethylene and polypropylene:

Transparent: 0.0005-0.001%(0.5-1g/100kg material)

Whitening: 0.005-0.05%(5-50g/100kg material)

Package

25kg fiber drum,with PE bag inside or as customer’s request.