Optical Brightener KCB

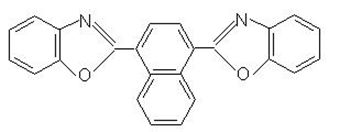

Structural formula

Chemical name: 1,4-bis(benzoxazolyl-2-yl)naphthalene

C.I.:367

CAS NO.: 5089-22-5/63310-10-1

Technical data:

Appearance: yellowish-green crystal powder

Content: ≥99.0%

Melting point: 210-212℃

Molecular formula: C24H14N2O2

Molecular weight: 362

Solubility: insoluble in water, soluble in organic solvents

Maximum absorption spectrum wavelength: 370nm

Maximum fluorescence emission wavelength: 437nm

Other features: good heat resistance and light resistance; good chemical stability, no reaction with plasticizers, foaming agents, crosslinking agents, etc., good compatibility with polymer materials, and no bleeding.

Application

Optical brightener KCB is one of the best products among many fluorescent whitening agents. Strong whitening effect, bright blue and bright color, it has good heat resistance, weather resistance and chemical stability. It is mainly used for the whitening of plastic and synthetic fiber products, and it also has obvious brightening effect on non-ferrous plastic products. It is also widely used in ethylene/vinyl acetate (EVA) copolymers, which is an excellent variety of optical brighteners in sports shoes. It is also widely used in PE, PP, PVC, PS, ABS, PMMA and other plastic films, molding materials, injection molding materials and polyester fibers. It also has a significant effect on the whitening of paints and natural paints. This variety is the lowest toxic among many varieties of whitening agents. The United States stipulates that it can be used for whitening food packaging materials.

Reference Dosage

For plastics or resins, the general dosage is 0.01-0.03%, that is, about 10-30 grams of BC-111 fluorescent whitening agent is added to 100 kilograms of plastic raw materials. The user can adjust the specific dosage of the whitening agent according to the requirements of whiteness. If an ultraviolet absorber such as titanium dioxide is added to the plastic raw material, the optimal amount of the whitening agent should be adjusted appropriately.

PE : 10-25g/100kg plastic raw material

PP : 10-25g/100kg plastic raw material

PS : 10-20g/100kg plastic raw material

PVC: 10-30g/100kg plastic raw material

ABS : 10-30g/100kg plastic raw material

EVA: 10-30g/100kg resin

If used in transparent plastic film, the reference dosage of brightener: 1-10g/100kg plastic raw material

Packing: 25kg cardboard drum lined with plastic bag or packed according to customer requirements