White objects generally slightly absorb blue light (450-480nm) in visible light (wavelength range 400-800nm), resulting in insufficient blue color, making it slightly yellowish, and giving people a sense of old and unclean due to the affected whiteness . To this end, people have taken different measures to whiten and brighten the items.

There are two commonly used methods, one is Garland whitening, that is, adding a small amount of blue pigment (such as ultramarine) to the pre-brightened item, covering the yellowish color of the substrate by increasing the reflection of the blue light part, making it appear whiter. Although garland can whiten, one is limited, and the other is that due to the reduction of the total amount of reflected light, the brightness is reduced, and the color of the item becomes darker. Another method is chemical bleaching, which fades the color by redox reaction on the surface of the object with pigment, so it will inevitably damage the cellulose, and the object after bleaching has a yellow head, which affects the visual experience. Fluorescent whitening agents discovered in the 1920s made up for the shortcomings of the above methods and showed incomparable advantages.

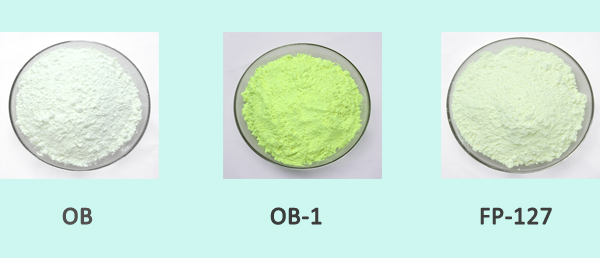

Fluorescent whitening agent is an organic compound that can absorb ultraviolet light and excite blue or blue-violet fluorescence. Substances with fluorescent whitening agent adsorbed can reflect the visible light irradiated on the object, and also The absorbed invisible ultraviolet light (wavelength is 300-400nm) is converted into blue or blue-violet visible light and emitted, and blue and yellow are complementary colors to each other, thus eliminating the yellow in the matrix of the article, making it white and beautiful. On the other hand, the emissivity of the object to the light is increased, and the intensity of the emitted light exceeds the intensity of the original visible light projected on the object to be processed. Therefore, the whiteness of the object seen by people’s eyes increases, thereby achieving the purpose of whitening.

Fluorescent whitening agents are a class of organic compounds with a special structure containing conjugated double bonds and good planarity. Under sunlight, it can absorb ultraviolet rays that are invisible to the naked eye (wavelength is 300~400nm), excite molecules, and then return to the ground state, part of the ultraviolet energy will disappear, and then converted into blue-violet light with lower energy (wavelength 420~480nm) emitted. In this way, the reflection amount of the blue-violet light on the substrate can be increased, thereby offsetting the yellow feeling caused by the large amount of yellow light reflection on the original object, and visually producing a white and dazzling effect.

The whitening of fluorescent whitening agent is only an optical brightening and complementary color effect, and cannot replace chemical bleaching to give the fabric true “white”. Therefore, if the fabric with dark color is treated with fluorescent whitening agent alone without bleaching , the satisfactory whiteness cannot be obtained. The general chemical bleaching agent is a strong oxidant. After the fiber is bleached, its tissue will be damaged to a certain extent, while the whitening effect of the fluorescent whitening agent is an optical effect, so it will not cause damage to the fiber tissue. Moreover, the fluorescent whitening agent has a soft and dazzling fluorescent color in sunlight, and because there is no ultraviolet light under incandescent light, it does not look as white and dazzling as in sunlight. The light fastness of fluorescent whitening agents is different for different varieties, because under the action of ultraviolet light, the molecules of the whitening agent will be gradually destroyed. Therefore, products treated with fluorescent whitening agents are prone to decrease in whiteness after long-term exposure to sunlight. Generally speaking, the light fastness of polyester brightener is better, that of nylon and acrylic is medium, and that of wool and silk is lower.

The light fastness and fluorescent effect depend on the molecular structure of the fluorescent whitening agent, as well as the nature and position of the substituents, such as the introduction of N, O, and hydroxyl, amino, alkyl, and alkoxy groups in heterocyclic compounds, which can help. It is used to improve the fluorescence effect, while the nitro group and the azo group reduce or eliminate the fluorescence effect and improve the light fastness.

Post time: Jan-14-2022